This is a new kind of filament that can be easily smoothed by D-Limonene. D-Limonene is an extract of “Orange skins”.

By smoothing, the individual layer loops can be made smooth and the resulting surface will be almost as clear as glass.

SBS-Glass Filamentarno Prototyper”

“T-Soft” is the name of the Transparent filaments, while “S-Soft” is indicating the solid SBS filaments.

This is a 1.75mm filament, based on Styrene-Butadene rubber (SBS), a material resembling car tires and the bottoms of shoes. It’s very sturdy! Polystyrene is a tough hard plastic kind that is SBS granting it’s durability. Polybutadene is rubbery, and this gives SBS its flexible-properties. Moreover, it’s internal structure makes it possible for SBS to return to its original shape after being stretched.

In short , the benefits of SBS are:

- Light, flexible, and strong. One of the few filaments to easily become smooth by applying orange extract ( D- Limonene) . This achieves the same effect as using acetone on ABS

- The Transparent colors became clear when D-Limonene is applied.

- Deep glassy transparent colors available as well as and some ” solid ” colors.

- Food Grade , so it is suitable for use in combination with food and toys.

- No smell while printing

- Flows beautifully during printing , the layers attach well.

- No thermal warp during printing.

- High constant quality

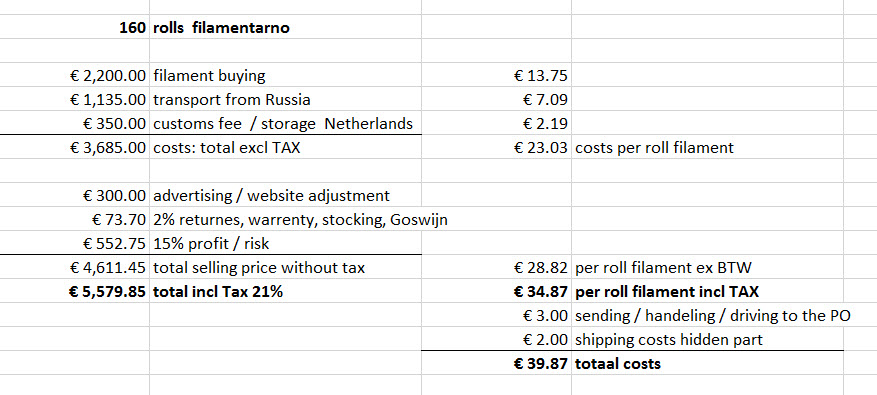

The price is pretty high, even when taking a low profit. This is how the price is built up:

The advantage over other filaments is that SBS – Glass can be disolved by “D- Limonene ” . D- Limonene has to be sprayed evenly over the 3D Print , after which the surface dissolves slightly and forms an uniform surface. After evaporation it creates a smooth skin. Such transparency with other filaments is not yet possible.

This evaporation can best be accelerated with a hair dryer after the application of D- Limonene .

Here are some examples of parts printed with SBS and then smoothed:

SBS Glass comes as 1.75mm filament coils at 750gr , packed in reseal-able zip lock bags, in a cardboard box .

Extruder temperature of 190 to 240 ° C ( 210-230 ° C recommended extruder temperature). The lower the temperature, the less oozing or stringing will occur. Oozing is the leakage of melted filament under the influence of gravity, when there is nothing being extruded. The effect of oozing when the printhead is “traveling’ to the next print island is called ‘ stringing ‘, or thin cobweb -like wires between the print areas.

We operate our printer at a printing temperature of 215 degrees, but the correct temperature. depends on measuring and geometry of your hotend .

The recommended bed temperature is 60 ° C on kapton or on a glasbed treated with “Gravity Spray ” or “3D Lac ” SBS Glass can also be printed on a not-heated bed .

Bowden

We have SBS tested with a direct-drive extruder. SBS can also be printed with a Bowden extruder, but may require the following adjustments:

- Reducing the force of the spring which applies the ‘clamp’ of the gear of the hotend . This is because SBS may deform plastically and by that can cause to much resistance in the filament tube .

- There must be a minimum distance between the drive of the filament and the tube . This because SBS is more flexible than standard filament, and should not have too much space to ‘ nod ‘ in front of the filament Bowden tube,.

Further data from SBS Glass:

- The modulus of elasticity of SBS-Glass is smaller than ABS. So the printed objects are pretty flexible. The elongation at break> 250%.

- SBS-Glass filament gives little or no odor when it is melted and when 3D printed. People with a very sensitive nose can smell the melted filament at 30 cm distance, primarily due to the added dyes. Solid transparent SBS has no smell.

- SBS Glass is approved for contact with food that is certified on the raw materials used in Russia. The dyes also have such a certificate.

- SBS Glass is approved for the manufacture of medical devices and toys in Russia.

- Both transparent and opaque colored plastics and metallics have the same characteristics.

- When a color is changed during 3D printing the printer’s settings won’t have to be changed.

- There is virtually no thermal warp, so it is easy to print!

- SBS is not prone to delamination.

- The 3D print is easy to detach from the printbed after cooling.

- SBS Glass does not absorb moisture! However: keep it in the pack to prevent it from collecting dust.

- The produced diameter is very constant: 1.75mm.

Mechanical and Chemical Data SBS Glass

| Print temperature | (it is recommended 210-220 ° C) 190-240 ° C |

| Solid | 1,01 g / cm 3 |

| Moister absorbtion | 0,07% |

| Pull modus | 1.350 MPa |

| Bend Modus | 1.450 MPa |

| Pull strength | 24 MPa |

| Stretch at Breach | 250% |

| Bend strength | 36 MPa |

| Shore (HSh) | 68 |

| Rockwell shore (HRB) | 118 |

| Izod Strike(23 ° C) | 3,5 kJ / m 2 |

| Izod Strike with carves (-30 ° C) | 2,8 kJ / m 2 |

| Izod-Carve Strength(23 ° C) | 35 J / m |

| Glas Transition Temperature (rubbery) | 80 O C |

| Softenings temperature | 76 o C |

| Krimp tijdens de vervaardiging van producten | 0,2-1,2% |

| Transparancy | 90% (Applies T-Soft) |

| Minimal Wall thickness | 0,3 mm |

| Diluent | |

| D-limonene: | SBS Glass can be solved with D- Limonene (made from orange peels ) . It is advisable to spray D- Limonene outside (or in a well ventilated area ) to the object until there’s a equal “film”on created. After processing , there remains a pleasant scent of citrus fruit ;-) .

Direct – or a few minutes- after spraying the D- Limonene had to be vaporized to stop the dissolving process, for example by using a hair dryer . This until the object is no longer sticky when touched . For thin walls start drying quickly, as otherwise the object itself melts quickly. |

At ” Vase Mode “, or a single extrusion of the skin of an object (like the ” spiral” function of Slic3R and Simplify3D) , then we use a low height = 25 % of the nozzle diameter. Thus, a low height of 0.20/0.25mm with a nozzle with 1mm diameter. The print speed depends on the ability of the hotend , but with a standard 40W / 24V heater we print the perimeter of 20-30mm/s and not accelerated.

- The wall thickness ( Path Width ) is optimal 1.5mm with a 1.0mm nozzle and a layer height of 0.3mm .

- The wall thickness ( Path Width ) is optimal 1.2mm with a 1.0mm nozzle and a layer height of 0.2mm .

- The wall thickness ( Path Width ) is optimal 1.0mm with a 1.0mm nozzle and a layer height of 0.1mm .