Waarschuwing! Hieronder verschillende profielen voor CraftWare voor bijzondere filamenten en afwijkende Nozzle maten. Deze profielen zijn experimenteel en zeker niet geschikt om mee te starten! Daarnaast is er inzicht nodig hoe deze profielen aangepast moeten worden voor specifieke objecten of eind resultaten. Niet alle profielen zijn door ons zelf getest, echter wel door diegene die ze ons heeft aangereikt. Om de profielen te downloaden met Chrome: rechts klikken op de (zwarte) link en “save link als” klikken. Bedankt Goswijn!

Warning! Below different profiles for CraftWare for special filaments and different nozzle sizes. These profiles are experimental and certainly not suitable to start with! In addition, it is necessary to understand how these profiles need to be adapted for specific objects or final results.

Not all profiles are tested by ourselves, however, they have been by the person who has sent them to us. Downloading with Chrome: right click and click “save link as”. Thanks Goswijn!

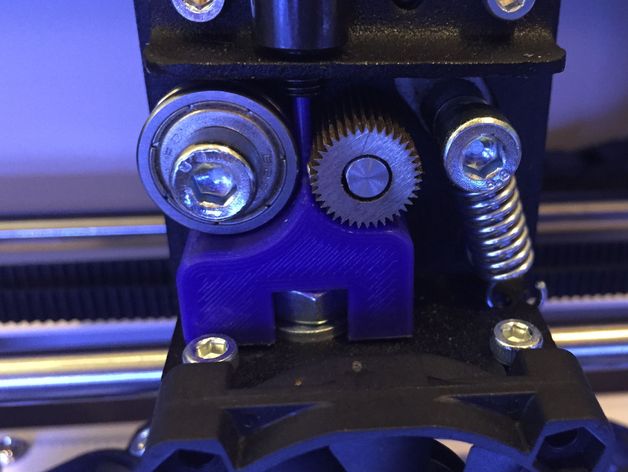

FilaFlex and NinjaFlex (by Goswijn Thijssen)

Printing with filaflex and NinjaFlex requires this addition for your extruder to print. (Print it in ABS or PETG, as PLA has a too low Glas transition temperature).

LayWood (by Goswijn Thijssen)

Be sure to remove the filament directly after print from the extruder (while it’s still hot). Otherwise it’s likely that the hotend will be massively clogged by charcoal. You surely need to take it apart and clean it. If so: see this post.

Taulman Bridge Nylon (by Goswijn Thijssen)

0.20mm Nozzle and PLA (by Bart ter Haar)

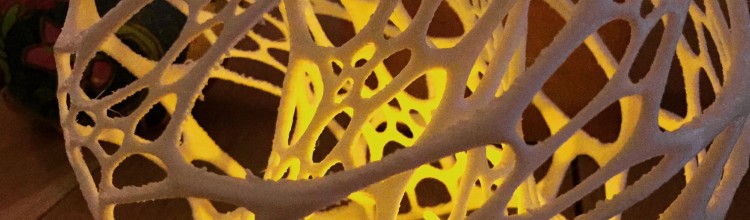

I use this profile for very delicate architectural models. See this post about how to deal with that kind of models.

Brons en koper / Brass and Copper filled filament (by Bart ter Haar)

Brass, copper – and maybe aluminium too – has to be extruded at lowest possible temperature, as the metal parts in the filament will conduct heat more than other filaments. That makes it more likely that the filament softens to early in the drive chain, at a point above the heatbreak, making the extruder to clog. test the minimum temp needed to extrude and set that value + 10 degrees in your slicer to avoid problems.